The goal of an LFG energy project is to convert LFG into a useful form of energy. Hundreds of LFG

energy projects currently operate in the United States, involving public and private organizations, small

and large landfills and various types of technologies. The most common LFG energy applications include:

• Electricity (power production a

nd

c

ogeneration) – LFG extracted from t

he

landfill is converted to electricity

• D

irect use of medium-Btu gas – treated LFG

is

u

sed as a direct source of fuel

• Upgrade to vehicle fuel or pipeline-quality

(high-Btu) gas – LFG is converted to produce

the equivalent of natural gas, CNG or LNG

For example, LFG is used to produce electricity

and heat in cogeneration applications. Direct-use

applications include heating greenhouses, firing

brick kilns and providing fuel to chemical and

automobile manufacturing businesses. Table 3-1

shows a breakdown of technologies used in

operational LFG energy projects in 2017.

The remainder of this chapter provides a brief

overview of design factors and technology options

for LFG energy projects, followed by a discussion

of considerations in technology selection.

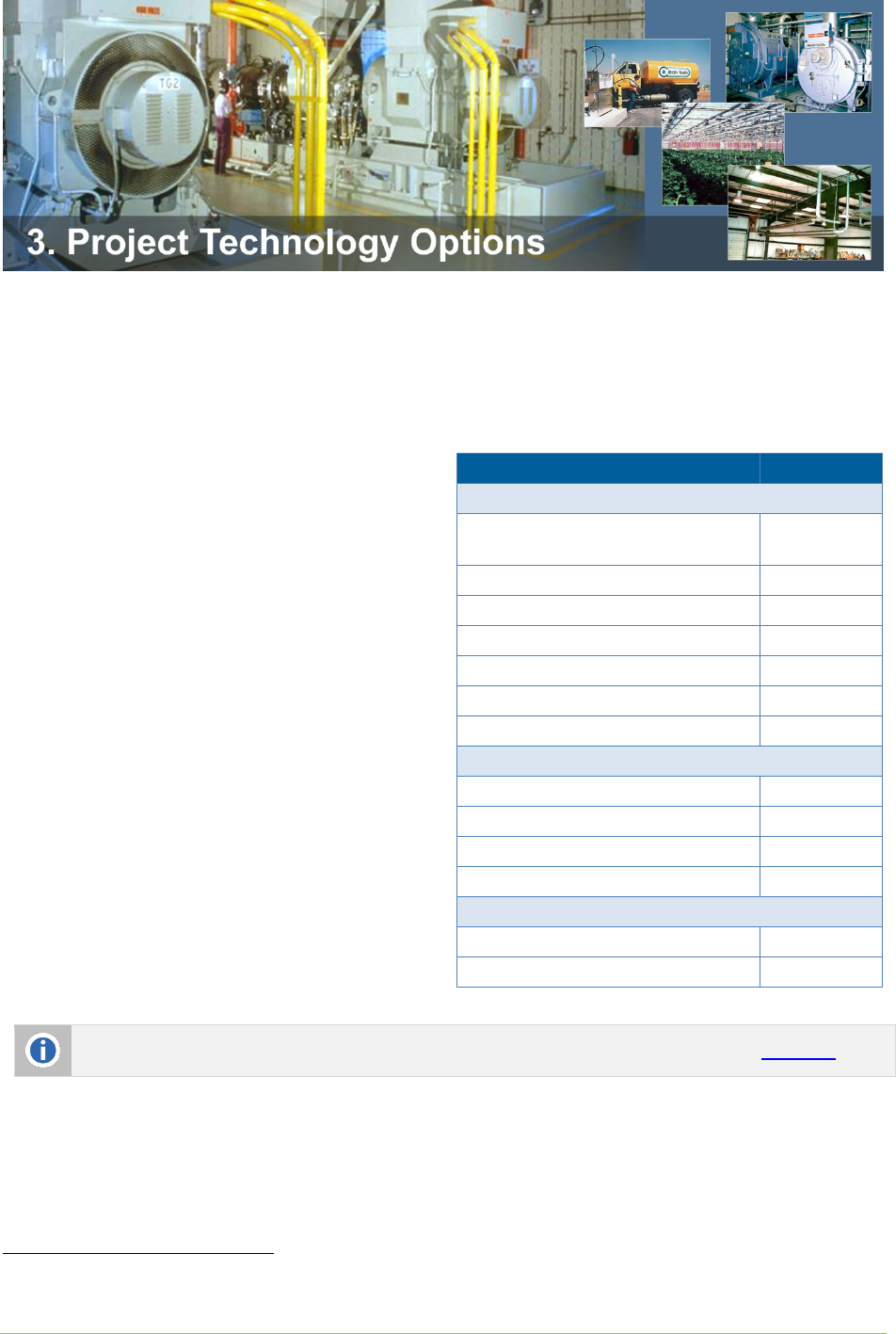

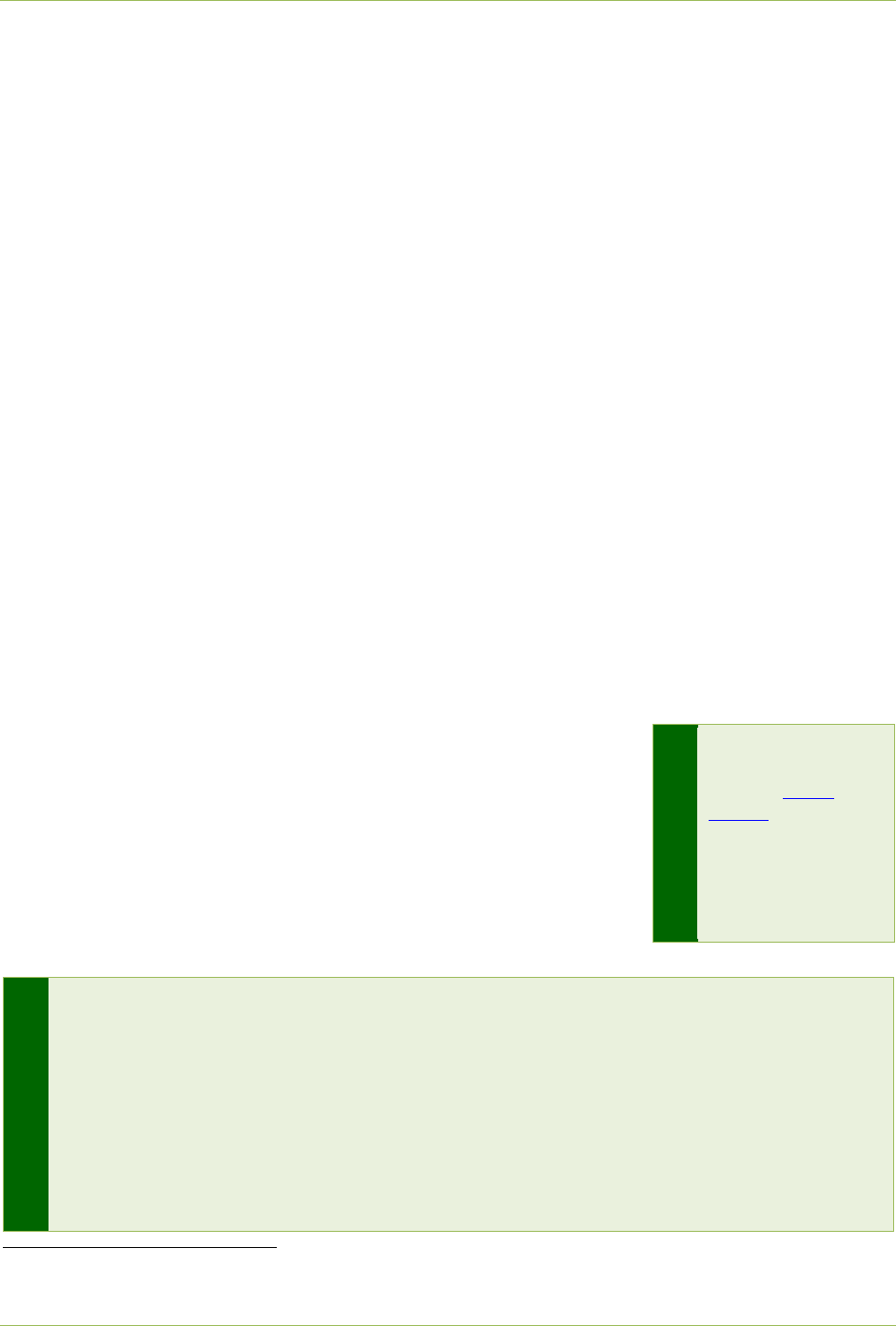

Table 3-1. Operational Project Technologies

Project Technology

Projects

1

Electricity Projects

Internal combustion engine

(reciprocating engine)

360

Cogeneration 47

Gas turbine 31

Microturbine 12

Steam turbine 11

Combined cycle 9

Stirling cycle engine 2

Medium-Btu Direct-Use Projects

Boiler 58

Direct thermal 43

Leachate evaporation 13

Greenhouse 6

Upgraded LFG Projects

High-Btu 36

Alternative fuel (CNG or LNG) 6

For more information about LFG collection, flaring and treatment system components, see Chapter 1.

U.S. EPA LMOP. Landfill and LFG Energy Project Database. June 2017.

Project Technology Options

1

3-1

LFG Energy Project Development Handbook

3.1 Design Factors

Selecting the best technology options for a project involves consideration of several key design factors,

beginning with estimating the LFG recovery potential for the landfill. In general, the volume of waste

controls the potential amount of LFG that can be extracted from the landfill. Site conditions, LFG

collection efficiency and the flow rate for the extracted LFG also significantly influence the types of

technologies and end use options that are most feasible for a project. Design considerations for gas

collection and treatment systems are presented below.

Gas Collection Systems

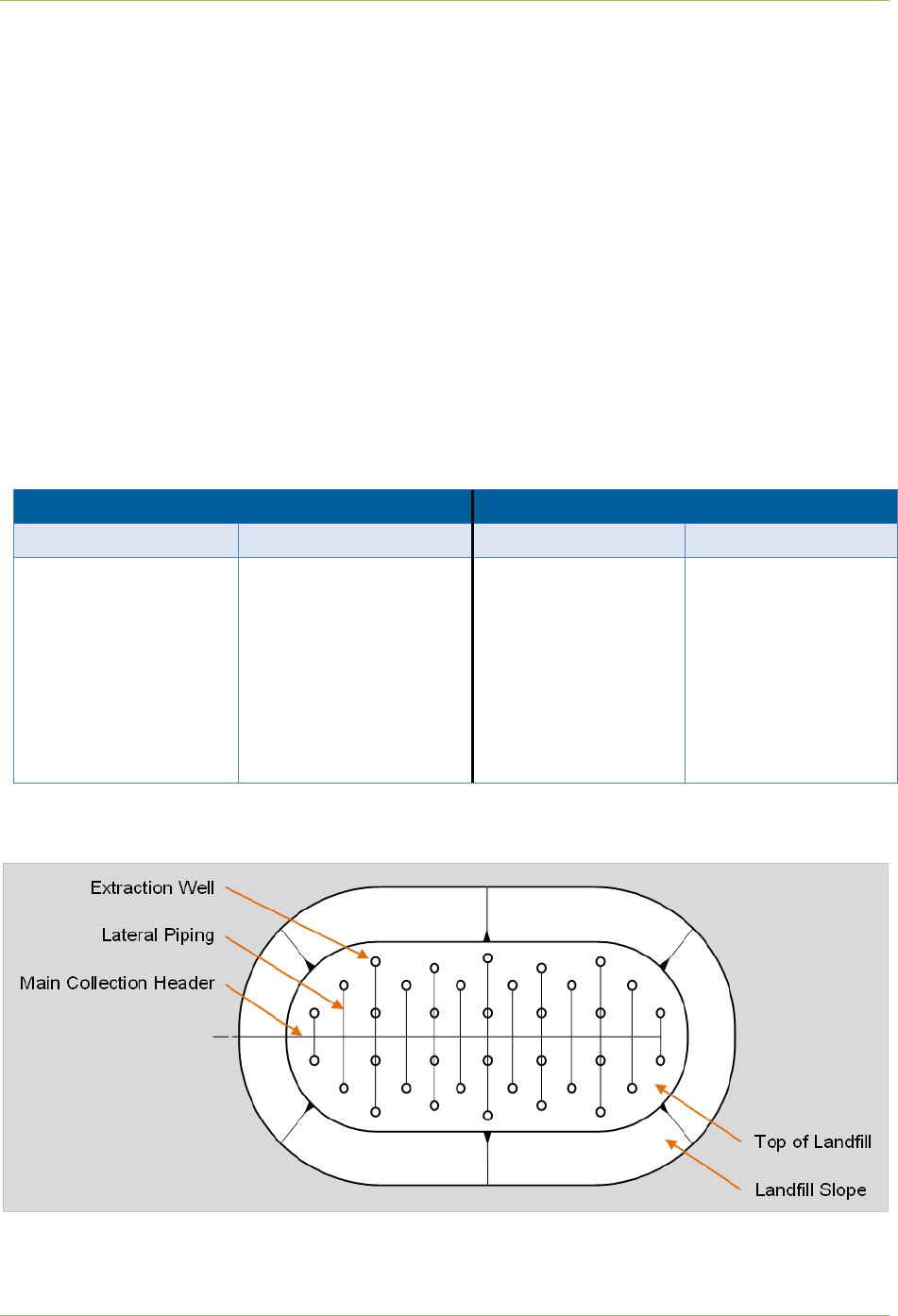

Collection systems can be configured as vertical wells, horizontal trenches or a combination of both.

Advantages and disadvantages of each type of well are listed in Table 3-2. Regardless of whether wells or

trenches are used, each wellhead is connected to lateral piping that transports the LFG to a main

collection header, as illustrated in Figure 3-1. The collection system should be designed so that the

operator can monitor and adjust the gas flow if necessary.

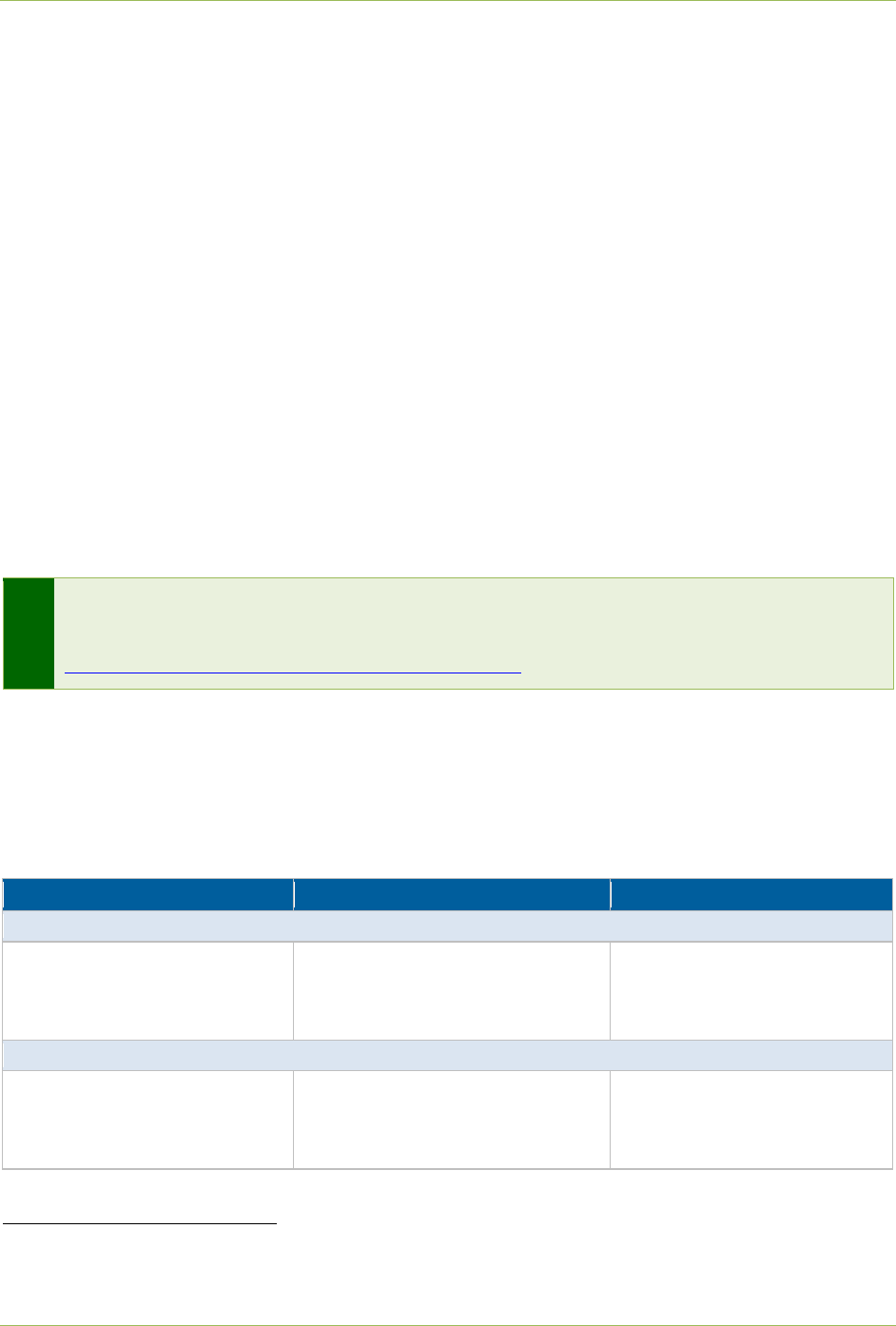

Table 3-2. Advantages and Disadvantages of Vertical and Horizontal LFG Collection Wells

Vertical Wells Horizontal Wells

Advantages Disadvantages Advantages Disadvantages

Minimal disruption of

landfill operations if

pl

aced in closed ar

ea

of

landf

ill

Most common design

Rel

iabl

e and

ac

cessible f

or

inspection and

pum

pi

ng

Increased operation

and maintenance

r

equired if installed i

n

ac

tive area of landfi

ll

Availability of

appr

opriate equipm

ent

Del

ayed gas collecti

on

if installed after site or

c

ell clos

es

Facilitates earlier

collection of LFG

Reduced need for

s

pecializ

ed

c

onstructi

on

equi

pm

ent

Allows extraction of

gas

from beneat

h an

ac

tive tipping ar

ea

on a deeper site

Increased likelihood

of air intrusion until

s

ufficiently cover

ed

wi

th wast

e

More prone to failure

bec

ause of floodi

ng

or

landfill settlemen

t

Figure 3-1. Sample LFG Extraction Site Plan

Project Technology Options 3-2

LFG Energy Project Development Handbook

LFG Treatment Systems

Before LFG can be used in an energy conversion process, it must be treated to remove condensate,

particulates and other impurities. Treatment requirements depend on the end use.

• Treatment systems for LFG electricity projects typically include a series of filters to remov

e

c

ontaminants that can damage components of the engine and turbine and reduce system efficiency

.

• M

inimal treatment is required for direct use of LFG in boilers, furnaces or kilns

.

• Advanced treatment is required to produce high-Btu gas for injection into natural gas pipelines or

p

roduction of alternative fuels

.

Tr

eatment systems can be divided into primary and secondary treatment processing. Most primary

processing systems include de-watering and filtration to remove moisture and particulates. Dewatering

can be as simple as physical removal of free water or condensate in the LFG using equipment often

referred to as “knockout” devices. It is common to use gas cooling and compression to remove water

vapor or humidity from the LFG. Gas cooling and compression have been used for many years and are

relatively standard elements of active LFG collection systems. Secondary treatment systems are designed

to provide much greater gas cleaning than is possible using primary systems alone. Secondary treatment

systems may employ multiple cleanup processes, including both physical and chemical treatments. The

type of secondary treatment depends on the constituents that need to be removed for the end use. Two of

the trace contaminants that may have to be removed from LFG are siloxanes and sulfur compounds.

• Siloxanes are found in household and commercial products that end up in solid waste and wastewate

r

(

a concern for landfills that take wastewater treatment sludge). Siloxanes in the landfill volatilize in

to

t

he LFG and are converted to silicon dioxide when the LFG is combusted. Silicon dioxide (the mai

n

c

onstituent of sand) collects on the inside of internal combustion engines and gas turbines and o

n

boi

ler tubes, potentially reducing performance and increasing maintenance costs. The need f

or

t

reatment depends on the level of siloxane in the LFG and on manufacturer recommendations for th

e

technology selected. Removal of siloxane can be both costly and challenging, so the decision to invest

i

n siloxane treatment is project dependen

t.

• Sulfur compounds, which include sulfides and disulfides

(for example, hydrogen sulfide), are corrosive in t

he

p

resence of moisture. These compounds will be a

t

r

elatively low concentrations, and the LFG may n

ot

r

equire any additional treatment at landfills acceptin

g

onl

y typical MSW. The compounds tend to be at highe

r

c

oncentration in landfills that accept C&D materials, a

nd

additional treatment is more likely to be necessary.

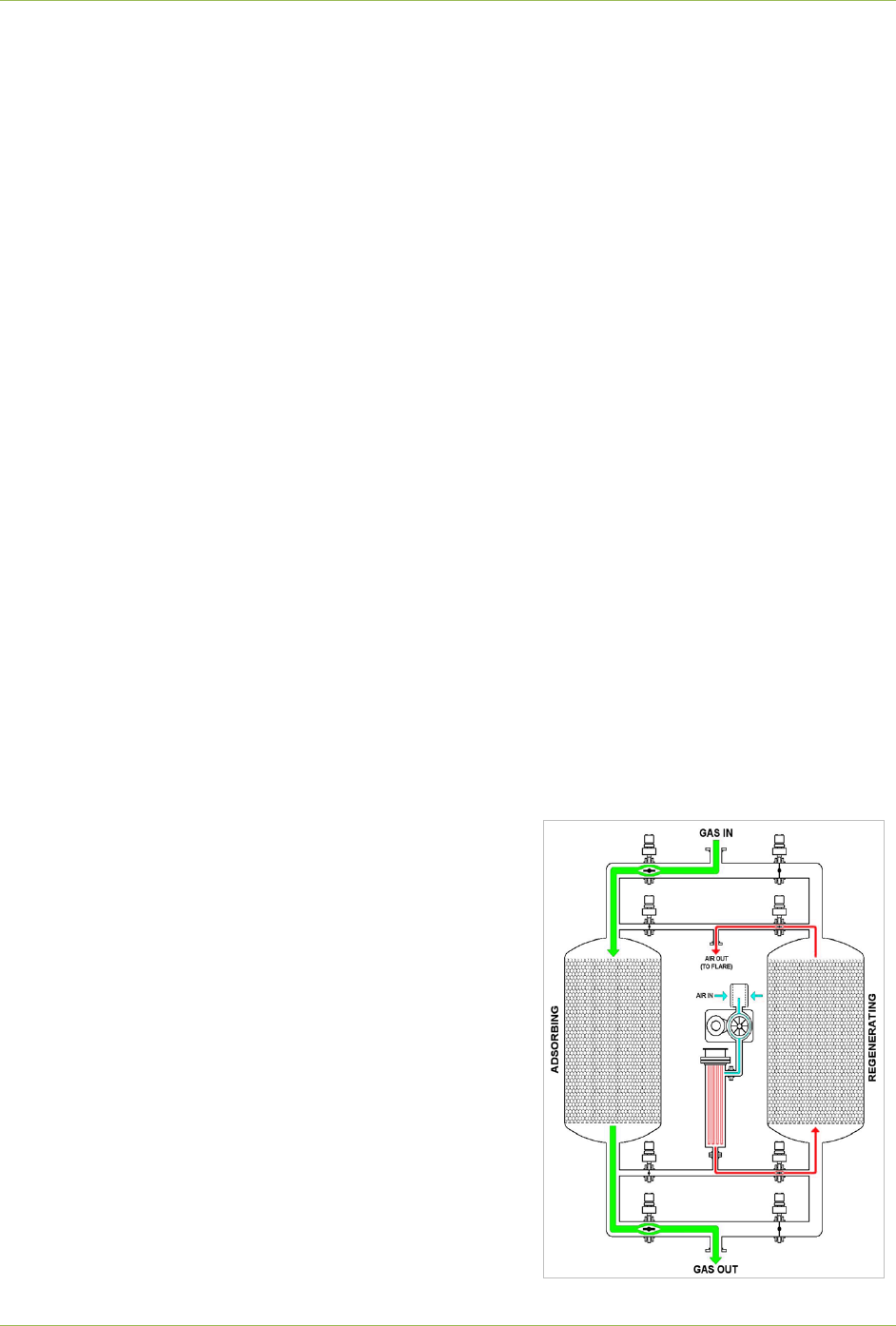

The most common technologies used for secondary treatment

are adsorption and absorption. Adsorption, which removes

siloxanes from LFG, is a process by which contaminants

adhere to the surface of an adsorbent such as activated carbon

or silica gel. Figure 3-2 illustrates a common type of

adsorption. Other gas treatment technologies that can remove

siloxanes include subzero refrigeration and liquid scrubbing.

Absorption (or scrubbing) removes compounds (such as

Figure 3-2. Siloxane Removal System

Project Technology Options 3-3

LFG Energy Project Development Handbook

sulfur) from LFG by introducing a solvent or solid reactant that produces a chemical/physical reaction.

Advanced treatment technologies that remove carbon dioxide, NMOCs and a variety of other

contaminants in LFG to produce a high-Btu gas (typically at least 96 percent methane) are discussed in

Section 3.4.

3.2 Electricity Generation

Producing electricity from LFG continues to be the most common beneficial use application, accounting

for about three-fourths of all U.S. LFG energy projects. Electricity can be produced by burning LFG in

devices such as an internal combustion engine, a gas turbine or a microturbine.

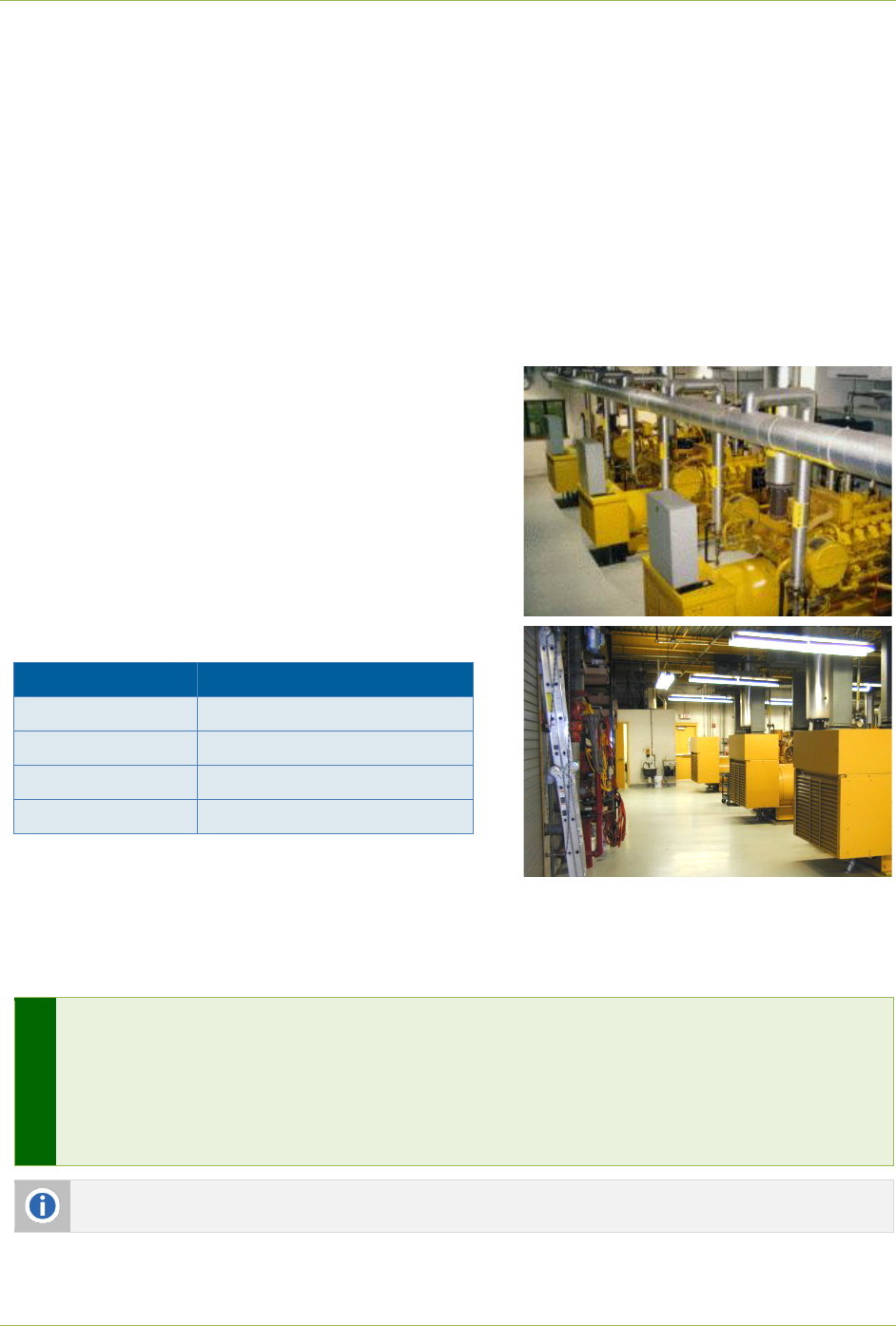

Internal Combustion Engines

The internal combustion e ng

ine is the most commonly us ed

conversion technology in LFG applications because of its

relatively low cost, high efficiency and engine sizes that

complement the gas output of many landfills (see Figure

3.3). Internal combustion e ngines have generally been us ed

at landfills where gas quantity is capable of producing 800

kW to 3 MW, or where sustainable LFG flow rates to the

engines are approximately 300 to 1,100 cfm at 50 percent

methane. Multiple engines can be combined together for

projects larger than 3 MW. Table 3-3 provides examples of

available sizes of internal combustion engines.

Table 3-3. Int

ernal Combustion Engine Sizes

Engine Size Gas Flow (50% Methane)

540 kW 204 cfm

633 kW 234 cfm

800 kW 350 cfm

1.2 MW 500 cfm

Figure 3-3. Internal Combustion Engines

cfm: cubic feet per minute kW: kilowatt MW: megawatt

Internal combustion engines are efficient at converting LFG into electricity, achieving electrical

efficiencies in the range of 30 to 40 percent. Even greater efficiencies are achieved in CHP applications

where waste heat is recovered from the engine cooling system to make hot water, or from the engine

exhaust to make low-pressure steam.

Examples

The Lycoming County Landfill Dual Cogeneration and Electricity Project in Pennsylvania,

an LMOP 2012 award-winning project, used an innovative permitting approach and a creative

power purchase agreement. LFG is combusted in four internal combustion engines (6.2 MW

total), which supplies 90 percent of the landfill complex’s power and thermal needs and 80

percent of the electricity needs of the Federal Bureau of Prisons’ Allenwood Correctional

Complex. The county receives revenue for the project, and the Bureau gains power price stability

and can count the LFG use toward meeting federal renewable energy requirements.

For more information about CHP, see the CHP Partnership’s Biomass Combined Heat and Power

Catalog of Technologies and the Catalog of CHP Technologies.

Project Technology Options 3-

4

LFG Energy Project Development Handbook

Gas Turbines

Gas turbines, as shown i

n Figure 3-4, are typically used in larger LFG

energy projects, where LFG flows exceed a minimum of 1,300 cfm and are

sufficient to generate a minimum of 3 MW. Gas turbine systems are

widely used in larger LFG electricity generation projects because they

have significant economies of scale. The cost per kW of generating

capacity drops as the size of the gas turbine increases, and the el ectric

generation e fficiency generally improves as well. Simple-cycle gas

turbines applicable to LFG energy projects typically achieve efficiencies of

20 to 28 percent at full load; however, these efficiencies drop substantially

when the unit is running at partial load. Combined-cycle configurations,

which recover the waste heat in the gas turbine exhaust to capture additional electricity, can boost system

efficiency to approximately 40 percent. As with simple-cycle gas turbines, combined-cycle configurations

are also less efficient at partial load.

Advantages of gas turbines are that they are more resistant to corrosion damage than internal combustion

engines and have lower nitrogen o xides emission rates. Additionally, gas turbines are relatively compact

and have low O&M costs compared with internal combustion e ngines. However, LFG treatment to

remove siloxanes may be required to meet manufacturer specifications.

A primary disadvantage of gas turbines is that they require high g as compression of 165 pound-force per

square inch gauge (psig) or greater. As a result, more of the plant’s power is required to run the

compression system (creating causing a high parasitic load loss).

Figure 3-4. Gas Turbine

Examples

LFG is piped 4 miles from the Arlington Landfill in Arlington, Texas, to the Fort Worth (Village

Creek) Wastewater Treatment Plant and is used to co-fire two 5.2-MW gas turbine generators

with heat recovery.

Residents from three municipalities and Waste Management, Inc., formed Green Knight

Economic Corporation, an independent non-profit organization that invested the revenue from the

sale of the LFG generated by a 9.9-MW power plant with three gas turbines.

Microturbines

Microturbines have been sold commercially for landfill and other biogas

applications since early 2001 (see Figure 3-5). Generally, costs for a

microturbine project are higher than for internal combustion engine

project costs based on a dollar-per-kW installed capacity.

2

However,

several reasons for using microturbine technology instead of internal

combustion engines include:

• Require less LFG volume than internal combustion engines

• Can use LFG with a lower percent methane (35 percent methane)

• Produce lower emissions of nitrogen oxides

• Can add and remove microturbines as gas quantity changes

• Interconnection is relatively easy because of the lower generation

capacity

Figure 3-5. Microturbine

2

Wang, Benson, Wheless. 2003. Microturbine Operating Experience at Landfills. Solid Waste Association of

North America (SWANA) 26th Annual Landfill Gas Symposium (2003), Tampa, Florida.

Project Technology Options 3-5

LFG Energy Project Development Handbook

LFG was not treated sufficiently in early microturbine applications, which resulted in system failures.

Typically, LFG treatment is required to remove moisture, siloxanes and other contaminants. This

treatment is composed of the following components:

• Inlet moisture separato

r

• Rotary vane type compressor

• C

hilled water heat exchanger (reducing LFG temperature to 40ºF

)

• C

oalescing filte

r

• L

FG reheat exchanger (to add 20 to 40ºF above dew point

)

• F

urther treatment of the moisture-free LFG in vessels charged with activated carbon or other medi

a

(optional)

M

icroturbines typically come in sizes of 30, 70 and 250 kW. Projects should use the larger-capacity

microturbines where power requirements and LFG availability can support them. The following benefits

can be gained by using a larger microturbine:

• Reduced capital cost (on a dollar-per-kW of installed capacity basis) for the microturbine itse

lf

• R

educed maintenance cos

t

• R

educed balance of plant installation costs — a reduction in the number of microturbines to reac

h a

given capacity will reduce piping, wiring and foundation costs

• I

mproved efficiency — the heat rate of the 250-kW microturbine is expected to be about 3.3 percen

t

b

etter than the 70-kW and about 12.2 percent better than the 30-

kW

Example

The Fort Benning Landfill in Fort Benning, Georgia is the site of a 250-kW capacity microturbine

project that has generated electricity for onsite use by the U.S. Army since November 2011. The

project is part of the U.S. Department of Defense’s high-priority environmental and energy goals.

When declining LFG flows led its original reciprocating engine project to close in the mid-1990s,

the All Purpose Landfill in Santa Clara, California partnered with a third-party developer for a new

750-kW capacity microturbine project which started up in late 2009. The project has three 250-kW

uni

ts and contributes to power purchaser Silicon Valley Power’s Renewable Energy Portfoli

o.

Electricity Generation Summary

Table 3-4 presents examples of typical costs for several technologies, including costs for a basic gas

treatment system typically used with each technology. The costs of energy generation using LFG can vary

greatly and depend on many factors, including the type of electricity generation equipment, its size, the

necessary compression and treatment system, and the interconnect equipment. Table 3-5 provides a

summary of the advantages and disadvantages associated with each electricity-generating technology.

Table 3-4. Examples of Typical Costs

3

Technology

Typical Capital Costs

($/kW)*

Typical Annual O&M

Costs ($/kW)*

Internal combustion engine (> 800 kW) $1,800 $250

Small internal combustion engine (< 800 kW) $2,500 $270

Gas turbine (> 3 MW) $1,500 $160

Microturbine (< 1 MW) $3,000 $280

* 2013 d

ollars kW: kilow

att M

W: megawatt

U.S. EPA LMOP. LFGcost-Web, Version 3.2.

Project Technology Options

3

3-6

LFG Energy Project Development Handbook

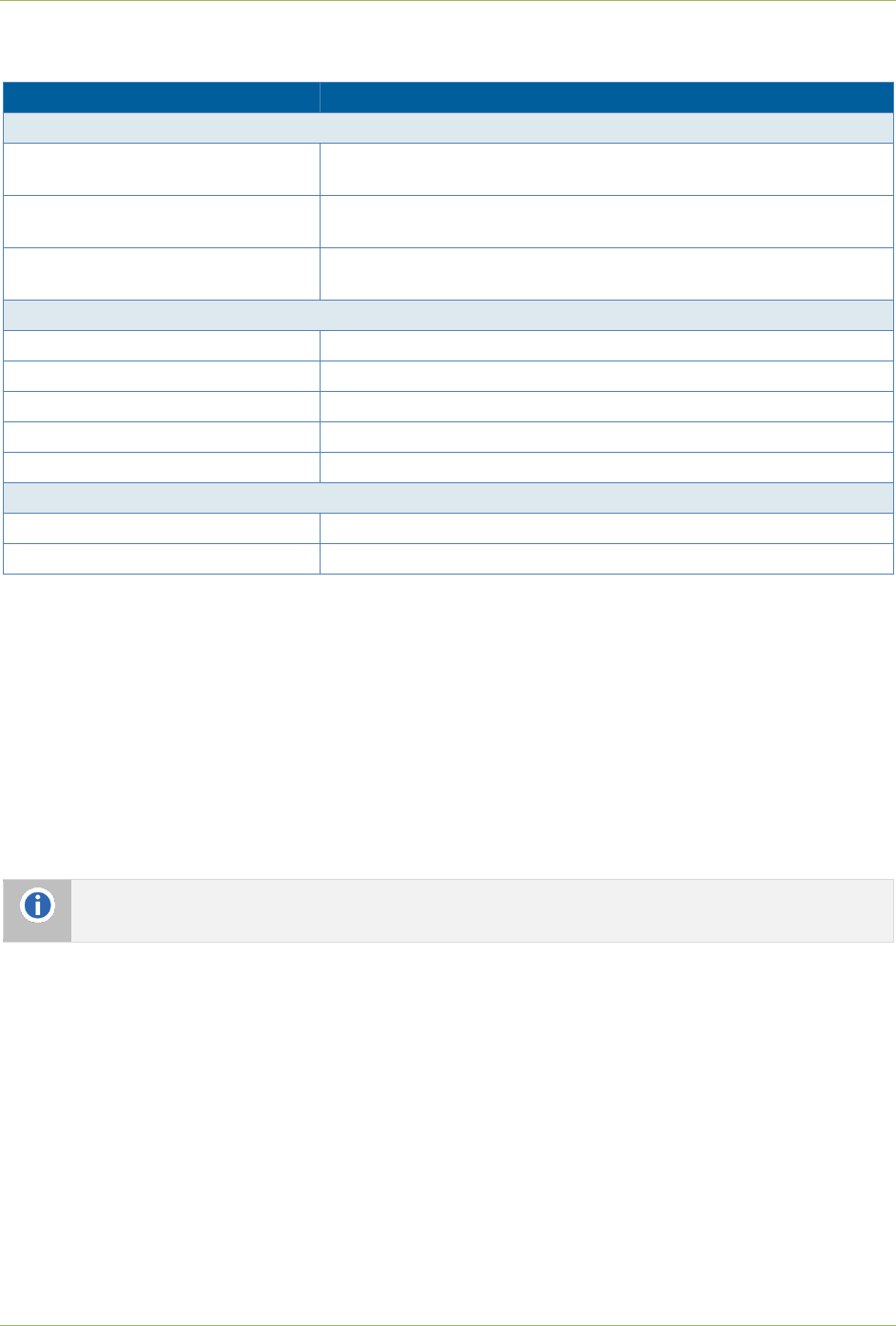

Table 3-5. Advantages, Disadvantages and Treatment Requirements Summary (Electricity)

Advantages

Disadvantages

Treatment

Internal combustion engine

High efficiency compared with gas turbines

and microturbines

Good size match with the gas output of

many landfills

Relatively low cost on a per kW installed

capacity basis when compared with gas

turbines and microturbines

Efficiency increases when waste heat is

recovered

Can add or remove engines to follow gas

recovery trends

Relatively high maintenance

costs

Relatively high air emissions

Economics may be marginal

areas with low electricity costs

At a minimum,

requires primary

treatment of LFG;

for optimal engine

performance,

secondary

treatment may be

necessary

Gas turbine

Cost per kW of generating capacity drops as

the size of the gas turbine increases, and

the efficiency improves as well

Efficiency increases when heat is recovered

More resistant to corrosion damage

Low nitrogen oxides emissions

Relatively compact

Efficiencies drop when the

unit is running at partial load

Requires high gas

compression

High parasitic loads

Economics may be marginal

in areas with low electricity

costs

At a minimum,

requires primary

treatment of LFG;

for optimal turbine

performance,

secondary

treatment may be

necessary

Microturbine

Requires lower gas flow

Can function with lower percent methane

Low nitrogen oxides emissions

Relatively easy interconnection

Ability to add and remove units

Economics may be marginal

in areas with low electricity

costs

Requires fairly

extensive primary

and secondary

treatment of LFG

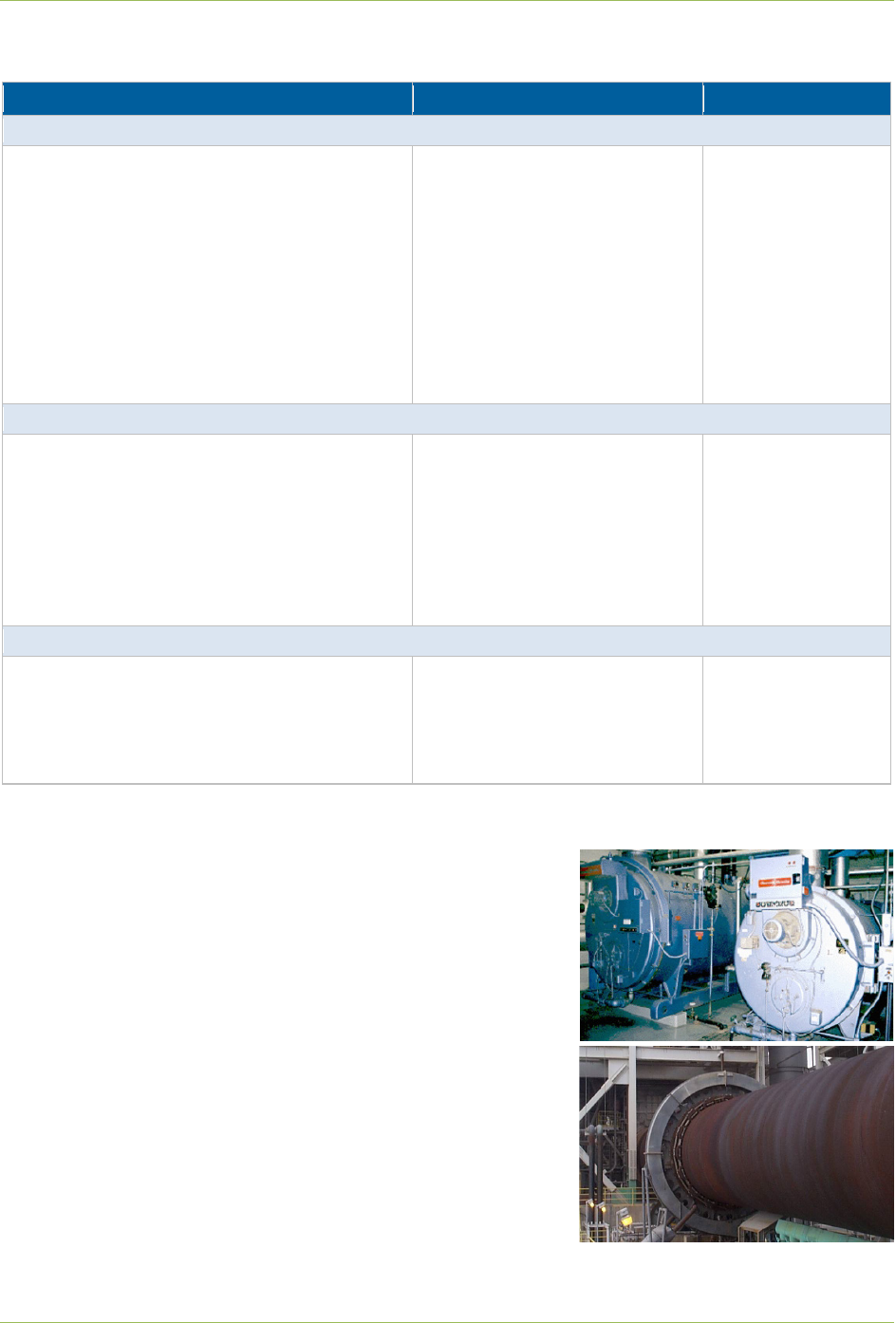

3.3 Direct Use of Medium-Btu Gas

Boilers, Dryers and Kilns

The simplest and often most cost-effective use of LFG is as a

medium-Btu fuel for boiler or industrial processes such as

drying operations, kilns and cement and asphalt production. In

these projects, the gas is piped directly to a nearby customer for

use in combustion equipment (Figure 3-6) as a replacement or

supplementary fuel. Only limited condensate removal and

filtration treatment are required, although some modifications of

existing combustion equipment might be necessary.

The end user’s energy requirements are an important consideration

in evaluating the sale of LFG for direct use. All gas that is

recovered must be used as available, or it is essentially lost, along

with associated revenue opportunities, because storing LFG is not

economical. The ideal gas customer, therefore, will have a steady

annual gas demand compatible with the landfill’s gas flow. When a landfill does not have adequate gas

Figure 3-6. Boi

ler and Cement Kiln

Project Technology Options 3-7

LFG Energy Project Development Handbook

flow to support the entire needs of a facility, LFG can still be used to supply a portion of the needs. For

example, only one piece of equipment (such as a main boiler) or set of burners is dedicated to burning

LFG in some facilities. In other cases, a facility might co-fire or blend LFG with other fuels.

Before an LFG energy direct-use project is pursued, LFG flow should be measured, if possible, and gas

modeling should be conducted as described in Chapter 2. For more details about project economics, see

Chapter 4.

Table 3-6 provides the expected annual LFG flows from landfills

of various sizes. While actual LFG flows will vary based on age,

composition, moisture and other factors of th

e waste, these

numbers can be used as a first step toward assessing the

c

ompatibility of customer gas requirements and LFG output

. A

rule of thumb for comparing boiler fuel requirements with LFG

output is that approximately 8,000 to 10,000 pounds per hour

(lb/hr) of steam can be generated for every 1 million metric tons of

wa

ste in place at a landfill; accordingly, a 5 million metric ton

landfill can support the needs of a large facility requiring about

45,000 lb/hr of

steam.

-

It may be possible to create a

steady gas demand by serving

multiple customers whose gas

requirements are

complementary. For example,

an asphalt producer’s summer

gas load could be combined

with a municipal building’s

winter heating load to create a

year round demand for LFG.

Tabl

e 3-6. Potential LFG Flows Based on Landfill Size

Landfill Size

(Metric Tons Waste-in-Place)

Annual LFG Flow

(MMBtu/yr)

Steam Flow Potential

(lb/hr)

1,000,000 100,000 10,000

5,000,000 450,000 45,000

10,000,000 850,000 85,000

MMBtu/yr: Million British thermal units per year lb/hr: pounds per hour

E

quipment modifications or adjustments may be necessary to accommodate the lower Btu value of LFG,

and the costs of modifications vary. Costs will be minimal if retuning the boiler burner is the only

modification required. The costs associated with retrofitting boilers will vary from unit to unit depending

on boiler type, fuel use and age of unit. Retrofitting boilers is typically required in the following

situations:

• Incorporating LFG into a unit that is co-firing with other fuels, where automatic controls are required

to sustain a co-firing application or to provide for immediate and seamless fuel switching in the event

of a loss in LFG pressure to the unit. This retrofit will ensure uninterruptible steam supply. Overall

costs, including retrofit costs (burner modifications, fuel train and process controls), can range from

$200,000 to $400,000.

• Modifying a unit that has a surplus or back-up steam supply so that the unit does not rely on the LFG

to provide an uninterrupted supply of steam (a loss of LFG pressure can interrupt the steam supply).

In this case, manual controls are implemented and the boiler operating system is not integrated into an

automatic control system. Overall costs can range from $100,000 to $200,000.

Another option is to improve the quality of the gas to such a level that the boiler will not require a retrofit.

While the gas is not required to have a Btu value as high as pipeline-quality gas, it must be between

medium- and high-Btu. This option eliminates the cost of a boiler retrofit and reduces maintenance costs

for cleaning deposits associated with the use of medium-Btu LFG.

Project Technology Options 3-8

LFG Energy Project Development Handbook

As described in Section 3.1, Design Factors, a potential problem for boilers is the accumulation of

siloxanes. The presence of siloxanes in the LFG causes a white substance to build up on the boiler tubes.

Operators who experience this problem typically choose to perform routine cleaning of the boiler tubes.

Boiler operators may also choose to install a gas treatment system to reduce the amount of siloxanes in

the LFG before it is delivered to the boiler.

For more information about the use of LFG in boilers, see the LMOP fact sheet on adapting boilers.

Examples

The NASA Goddard Flight Center became the first federal facility to burn LFG to meet energy

needs.

LFG captured from the Lanchester Landfill in Narvon, Pennsylvania, is used for multiple

purposes, including boilers, heaters, thermal oxidizers, ovens, engines and turbines.

For the St. John’s LFG Energy Project in Portland, Oregon, LFG provides a stable, competitively

priced fuel source for lime kilns. Other benefits include lower utility costs and lower emissions.

In Blythe, Georgia, a Clay Mine LFG Application involves the use of LFG to fuel flash drying

operations in the processing of mined clay.

Infrared Heaters

Infrared heating, using

LFG as a fuel source, is ideal for facilities with

space heating needs that are located near a landfill (Figure 3-7).

Infrared heating creates high-intensity energy that is safely absorbed

by surfaces that warm up. In turn, these surfaces release heat into the

atmosphere and raise the ambient temperature. Infrared heating

applications for LFG have been successfully employed at several

landfill sites in Canada, Europe and the United States.

Infrared heaters require a small amount of LFG to operate, are

relatively inexpensive, and are easy to install. Current operational projects (some of which have multiple

heaters) use between 10 and 150 cfm. Infrared heaters do not require pretreatment of the LFG, unless

siloxanes are present in the gas. One heater is typically required for every 500 to 800 square feet. Each

heater costs approximately $3,000 and the cost of interior piping to connect the heaters within the

building ceilings ranges from approximately $20,000 to $30,000.

Figure 3-7. Infrared Heater

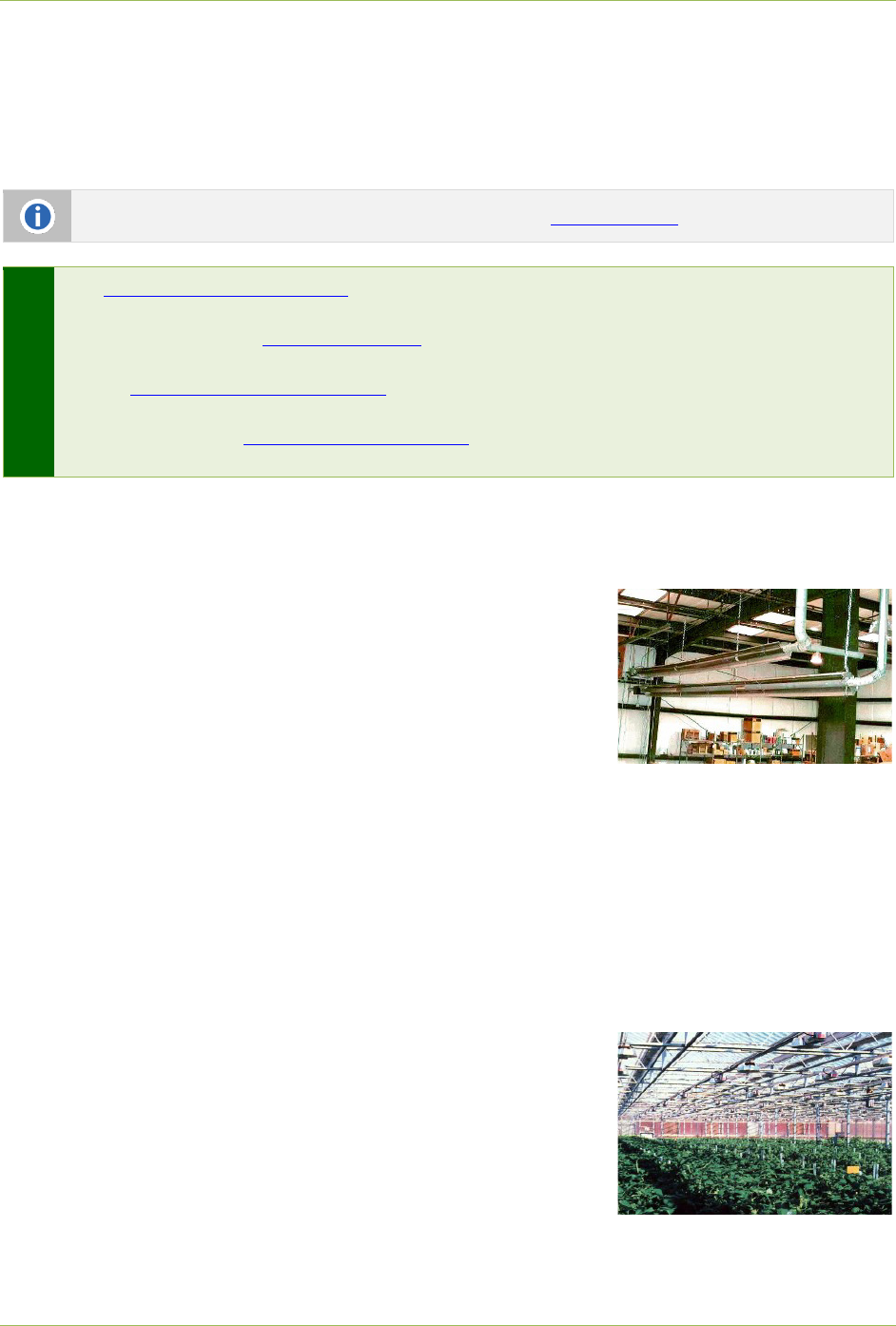

Gr

eenhouses

LFG can be used to provide heat for greenhouses, power grow lights

and heat water used in hydroponic plant cultures (Figure 3-8). The

costs for using LFG in greenhouses are highly dependent on how the

LFG will be used. If the grow lights are powered by a microturbine,

then the project costs would be similar to an equivalent microturbine

LFG energy project. If LFG is used to heat the greenhouse, the cost

incurred would be the cost of the piping and of the technology used,

such as boilers.

Figure 3-8. Greenhouse

Project Technology Options 3-9

LFG Energy Project Development Handbook

Artisan Studios

Artisan studios with energy-intensi

ve

activities such as creating glass, metal, or

pottery (Figure 3-9) offer another

opportunity for the beneficial use of LFG.

This application does not require a large

amount of LFG and can be coupled with a

commercial project. For example, a gas flow

of 100 cfm is sufficient for a studio that

houses glass-blowing, metalworking or

pottery kilns.

Figure 3-9. LFG-Powered Glass Studio

Examples

Infrared heaters are used in maintenance facilities at the I-95 Landfill in Virginia.

Several greenhouses have been constructed near landfills to take advantage of the energy

cost savings, including the Rutgers University EcoComplex Greenhouse.

The first U.S. artisan project to use LFG was at the EnergyXchange at the Yancey-Mitchell

Landfill in North Carolina. LFG is used at this site to power two craft studios, four

greenhouses, a gallery and a visitor center.

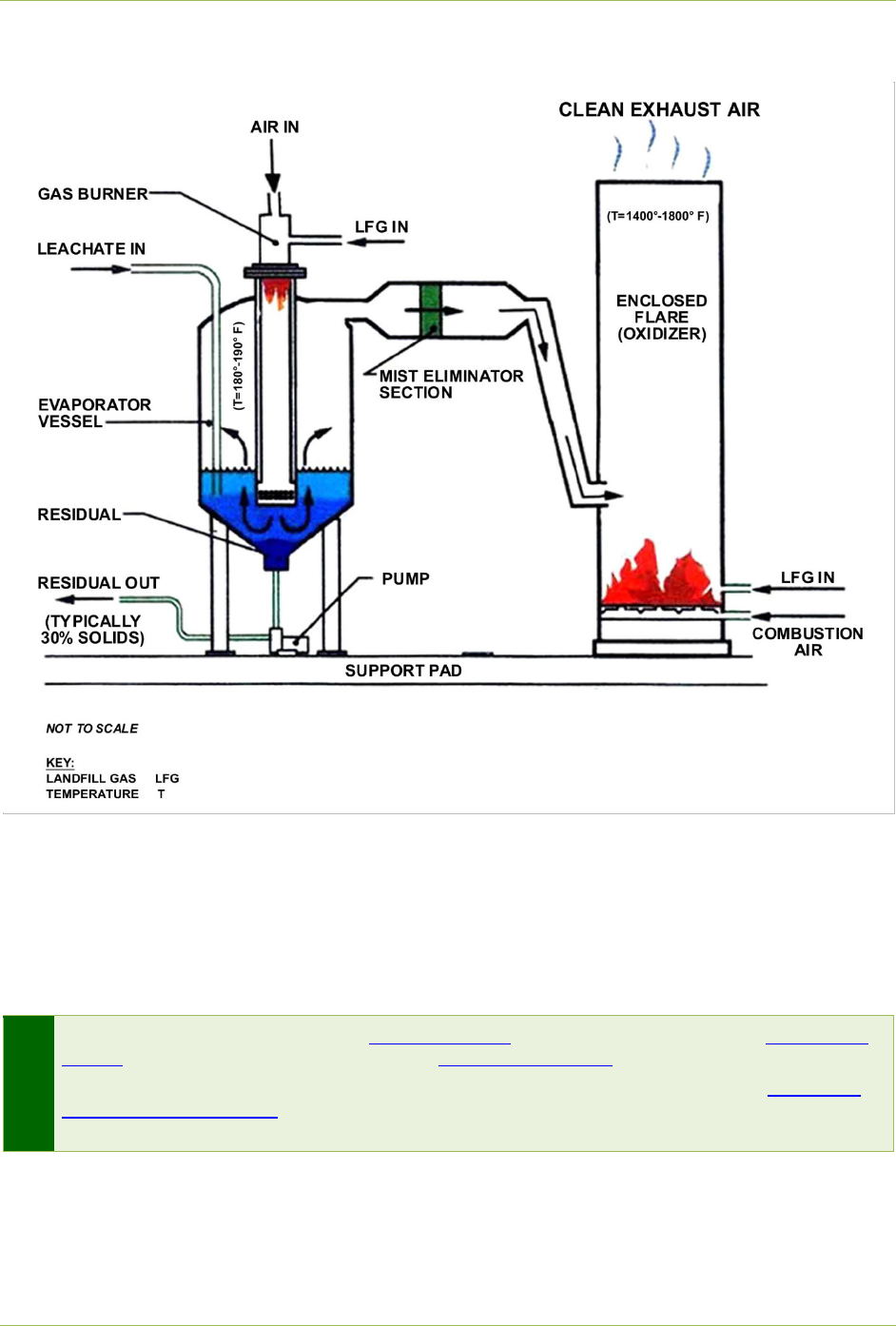

Leachate Evaporation

Leachate evaporation using LFG, shown in Figure 3-10, is a

good option for landfills where leachate disposal at a publicly

owned treatment works (POTW) plant is unavailable or

expensive. LFG is used to evaporate leachate to a more

concentrated and more easily discarded effluent volume (Figure

3-11).

Evaporators are available in sizes to treat 10,000 to 30,000

gallons per day (gpd) of leachate. Capital costs range from

$300,000 to $500,000. O&M costs range from $70,000 to

$95,000 per year. When a system is owned and operated by a

third party, long-term contracts will typically assess costs based

on the volume of leachate evaporated. Some economies of scale

are realized for larger size vessels, as shown in Table 3-7.

Table 3-7. Cost of Leachate Evaporation

4

Capacity Cost

30,000 gpd $0.05 - $0.06 per gallon

20,000 gpd $0.06 - $0.9 per gallon

10,000 gpd $0.10 - $0.15 per gallon

gpd: gallons per day

Figure 3-10. Leachate Evaporator

U.S. EPA LMOP. LFGcost-Web, Version 3.2.

Project Technology Options

4

3-10

LFG Energy Project Development Handbook

Figure 3-11. Leachate Evaporation Diagram

Biofuel Production

LFG can also be used to heat boilers in plants that produce biofuels including biodiesel and ethanol. In

this case, LFG is used directly as a fuel to offset another fossil fuel. Alternatively, LFG can be used as

feedstock when it is converted to methanol for biodiesel production.

Example

s

Leachate evaporation is used at the Centralia Landfill in Centralia, Washington, the J.J. Brunner

Landfill in Zelienople, Pennsylvania, and the Earthmovers Landfill in Elkhart, Indiana.

One example of an LFG biofuel project is located in Sioux Falls, South Dakota. The Sioux Falls

Regional Sanitary Landfill supplies LFG to POET, a producer of biorefined products, for use in a

wood waste-fired boiler, which generates steam for use in ethanol production.

Project Technology Options 3-11

LFG Energy Project Development Handbook

Direct Use of Medium-Btu Gas Summary

A summary of the advantages and disadvantages of direct-use technologies is presented in Table 3-8.

Table 3-8. Advantages, Disadvantages and Treatment Requirements Summary (Direct-Use)

Advantages

Disadvantages

Treatment

Boiler, dryer and kiln

Uses maximum amount of recovered gas flow

Cost-effective

Lim

ited condensate removal and filtrati

on

t

reatment is requir

ed

Does not require large amount of LFG and can

be blended with other fuels

Cost is tied to

length of pipeline;

ener

gy user mus

t

be nearby

Need to improve quality of

gas or retrofit equipment

Infrared heater

Relatively inexpensive

Easy to install

Does

not require a large amount of

gas

Can be coupled with another energy project

Seasonal use

may limit LFG

ut

ilizati

on

Limited condensate removal

and filtration treatment

Leachate evaporation

Good option for landfill where leachate disposal

is expensive

High capital costs

Limited condensate removal

and filtration treatment

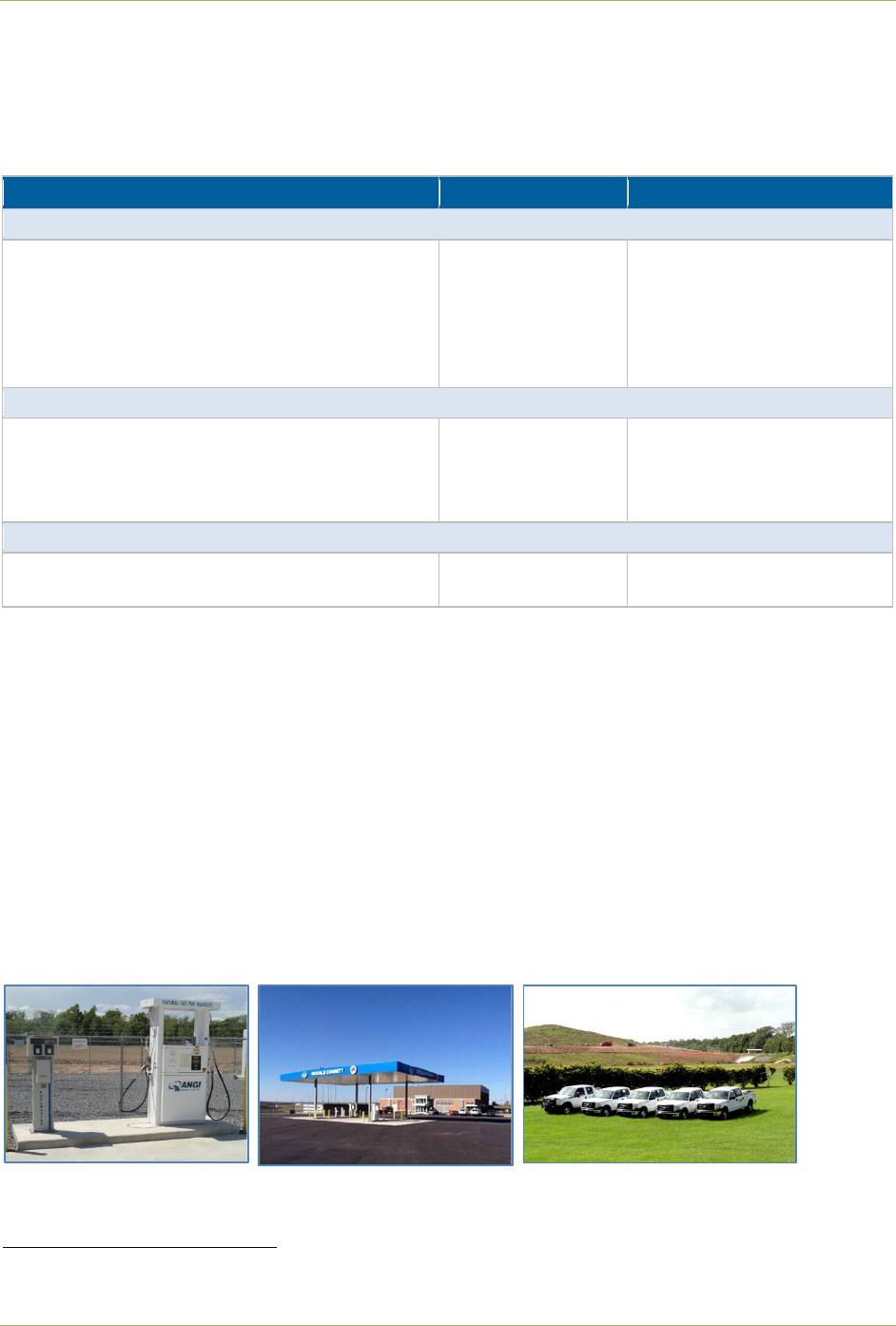

3.4 Conversion to High-Btu Gas

LFG can be used to produce the equivalent of pipeline-quality gas (natural gas), CNG or LNG, subject to

state regulations. Pipeline-quality gas can be injected into a natural gas pipeline used for an industrial

purpose. Alternatively, CNG and LNG can also be used to fuel vehicles at the landfill (such as water

trucks, earthmoving equipment, light trucks and autos), fuel refuse-hauling trucks (long-haul refuse

transfer trailers and route collection trucks) and supply the general commercial market (Figure 3-12).

Recent capital costs of high-Btu processing equipment have ranged from $2,600 to $6,000 per scfm of

LFG. The annual cost to provide electricity to operate and maintain these systems ranges from $500,000

to $5.0 million.

5

Project costs depend on the purity of the gas required by the receiving pipeline or energy

end user as well as the size of the project. Some economies of scale can be achieved when larger

quantities of high-Btu gas can be produced.

Figure 3-12. CNG Stations and CNG-fueled Vehicles

5

U.S. EPA LMOP. LFGcost-Web, Version 3.2.

Project Technology Options 3-12

LFG Energy Project Development Handbook

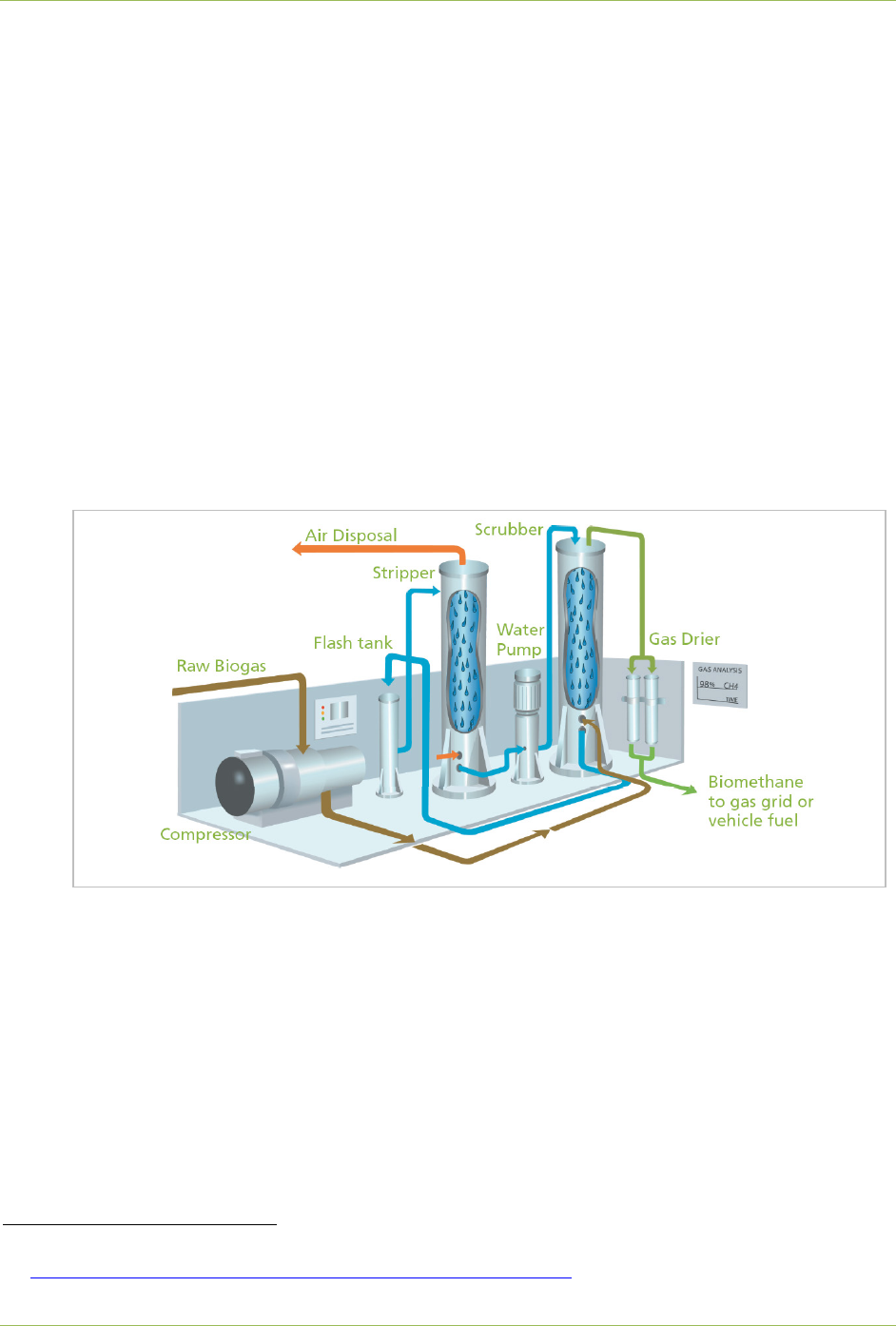

LFG can be converted into a high-Btu gas by increasing its methane content and, conversely, reducing its

carbon dioxide, nitrogen and oxygen content. In the United States, four methods have been commercially

employed (beyond pilot testing) to remove carbon dioxide from LFG:

• Water Scrubbing. Water scrubbing consists of a high-pressure biogas flow into a vessel colum

n

where carbon dioxide and some other impurities, including hydrogen sulfide, are removed by dilution

i

n water that falls from the top of the vessel in the opposite direction of the gas flow. The wat

er

s

crubbing process is illustrated in Figure 3-13. Methane is not removed because it has less diluti

on

c

apability. The pressure is set at a point where only the carbon dioxide can be diluted; normall

y

be

tween 110 and 140 pounds per square inch (psi). The water that is used in the scrubbing process i

s

t

hen stripped in a separate vessel to be used again, making this system a closed loop that keeps wate

r

c

onsumption low. The gases resulting from the stripping process (the same that were removed fr

om

the biogas) are then released or flared. Generally, no chemicals are required for the water scrubbing

pr

ocess, making it an attractive and popular technolog

y.

It is important to note that this technology will not remove certain contaminants such as oxygen and

n

itrogen that may be present in the raw biogas. This limitation may be an important variable when th

e

e

nd use of the cleaned gas is considered

.

F

igure 3-13. Water Scrubbing Unit Flow Schematic

6

• Amine Scrubbing. Selexol, a physical solvent that preferentially absorbs gases into the liquid phase,

is the most common amine used in amine scrubbing systems to convert LFG to high-Btu gas. A

ty

pical Selexol-based plant employs the following steps

:

L

FG compression (electric drive, LFG-fired engine drive or product gas-fired engine drive

)

Moisture removal using refrigeration

H

ydrogen sulfide removal in a solid media bed (using an iron sponge or a proprietary media

)

NM

OC removal in a primary Selexol absorbe

r

C

arbon dioxide removal in a secondary Selexol absorbe

r

The LFG is placed in contact with the Selexol liquid in a Selexol absorber tower. NMOCs are

generally hundreds to thousands of times more soluble than methane. Carbon dioxide is about 15

American Biogas Council. Biogas Processing for Utilities. February 2012.

http://www.americanbiogascouncil.org/biogasProcessing/biogasProcessing.pdf.

Project Technology Options

6

3-13

LFG Energy Project Development Handbook

times more soluble than methane. Solubility also is enhanced with pressure, facilitating the separation

of NMOCs and carbon dioxide from methane.

• Molecular Sieve. A typical molecular sieve plant employs compression, moisture removal and

hydrogen sulfide removal steps, but relies on vapor-phase activated carbon to remove NMOC and a

molecular sieve to remove carbon dioxide. Once exhausted, the activated carbon can be regenerated

through a depressurizing heating and purge cycle. The molecular sieve process is also known as

pressure swing adsorption.

• Membrane Separation. A typical membrane plant employs compression, moisture removal and

hydrogen sulfide removal steps, but relies on activated carbon to remove NMOCs and membranes to

remove carbon dioxide. Activated carbon removes NMOCs and protects the membranes. The

membrane process takes advantage of the physical property that gases, under the same conditions,

will pass through polymeric membranes at differing rates. Carbon dioxide passes through the

membrane approximately 20 times faster than methane. Pressure is the driving force for the

separation process.

Air intrusion is the primary cause for the presence of oxygen and nitrogen in LFG and can occur when air

is drawn through the surface of the landfill and into the gas collection system. Air intrusion can often be

minimized by adjusting well vacuums and repairing leaks in the landfill cover. In some instances, air

intrusion can be managed by sending LFG from the interior wells directly to the high-Btu process, and

sending LFG from the perimeter wells (which often have higher nitrogen and oxygen levels) to another

beneficial use or emissions control device. Membrane separation can achieve some incidental oxygen

removal, but nitrogen — which represents the bulk of the non-methane/non-carbon dioxide fraction of

LFG — is not removed. A molecular sieve can be configured to remove nitrogen by proper selection of

media. Nitrogen removal, in addition to carbon dioxide removal, requires a two-stage molecular sieve

pressure swing adsorption.

Compressed Natural Gas

The membrane separation and m olecular sieve processes scale down m ore

economically to smaller plants for CNG production. For this reason, these

technologies are more likely to be used for CNG production than the

Selexol (amine scrubbing) process. The estimated annualized capital and

operating costs of CNG production for membrane separation processes

capable of handling various gas flows ranges from $1.64 to $2.82 per

gasoline gallon equivalent (GGE).

7

elxampE

In Rochester, New

Hampshire, LFG

from the TREE

Landfill is processed

into pipeline-quality

gas and piped 12.7

miles to the

University of New

Hampshire.

le Examp

The Dane County BioCNG™

Vehicle Fueling Project located in Dane County, Wisconsin, was

recognized as an LMOP 2011 award winner for its successful generation of electricity from landfill

methane as well as its use of excess LFG to produce CNG that fuels the county’s parks and

public works department trucks. The system originally produced 100 gallons of gasoline

equivalent (GGE) per day and expanded to produce 250 GGE per day in 2013.

St. Landry Parish in Louisiana was recognized as a 2012 LMOP award winner for its successful

LFG-to-CNG project. The Parish originally converted 50 cfm of LFG into 250 GGE of CNG per

day, and expanded the project in 2015 to create a total of 630 GGE per day. The CNG is used to

fuel government vehicles including cars, trucks and vans. Benefits from the project include better

air quality and environmental education opportunities for the community.

7

U.S. EPA LMOP. LFGcost-Web, Version 3.2.

Project Technology Options 3-14

LFG Energy Project Development Handbook

Liquefied Natural Gas

LNG can be generated from LFG that is first converted to CNG. The CNG produced from LFG is

liquefied to produce LNG using conventional natural gas liquefaction technology. When assessing this

technology, two factors should be considered:

• Carbon dioxide freezes at a temperature higher than methane liquefies. To avoid “icing” in the plant,

t

he CNG produced from LFG must have the lowest possible level of carbon dioxide. The low carb

on

d

ioxide requirement favors a molecular sieve over a membrane separation process, or at least favor

s

upg

rading the gas produced by the membrane process with a molecular sieve. Water scrubbing also i

s

a

n optio

n.

• N

atural gas liquefaction plants have generally been “design-to-order” facilities that process larg

e

q

uantities of LNG. A few manufacturers offer smaller, pre-packaged liquefaction plants that hav

e

de

sign capacities of 10,000 gpd or greater

.

U

nless the nitrogen and oxygen content of the LFG is very low, additional steps must be taken to remove

nitrogen and oxygen. Liquefier manufacturers desire inlet gas with less than 0.5 percent oxygen, citing

explosion concerns. Nitrogen needs to be limited to produce LNG with a methane content of 96 percent.

The cost of LNG production is estimated to be $0.65/gallon for a plant producing 15,000 gpd of LNG. A

plant producing 15,000 gpd of LNG requires 3,000 scfm of LFG and would require a capital investment

approaching $20 million.

8

Example

In 2009, a high-tech fuel plant was opened in Livermore, California, that demonstrates the

viability of LFG as an alternative transportation fuel. LFG processed from the Altamont Sanitary

Landfill generates LNG that is used to fuel ~300 garbage trucks. More information about the

Altamont Landfill Gas to Liquefied Natural Gas Project is available from LMOP’s website.

Conversion to High-Btu Gas Summary

Table 3-9 summarizes the advantages and disadvantages of converting LFG to high-Btu gas.

Table 3-9. Advantages, Disadvantages and Treatment Requirements Summary (High-Btu)

Advantages

Disadvantages

Treatment

Pipeline-quality gas

Can be sold into a natural gas

pipeline

Increased cost that results from

tight management of wellfield

oper

ation needed to limit oxy

gen

and nitrogen intrusion into LFG

Requires extensive and

potentially expensive LFG

processing

CNG or LNG

Alternative fuels for vehicles

at the landfill or refuse hauling

t

rucks, and for supply to t

he

general commercial market

Increased cost that results from

tight management of wellfield

oper

ation needed to limit oxy

gen

and nitrogen intrusion into LFG

Requires extensive and

potentially expensive LFG

processing

8

Pierce, J. SCS Engineers. 2007. Landfill Gas to Vehicle Fuel: Assessment of Its Technical and Economic

Feasibility. SWANA 30th Annual Landfill Gas Symposium (March 4 to 8, 2007), Monterey, California.

Project Technology Options 3-15

LFG Energy Project Development Handbook

3.5 Selection of Technology

The primary factor in choosing the right project configuration for a particular landfill is the projected

expense versus the potential revenue. If a suitably interested customer is located nearby, a medium-Btu

option should be thoroughly examined. An energy user that requires gas 24 hours per day, 365 days a

year, is the best match for an LFG energy project, since intermittent or seasonal LFG uses typically result

in wasting gas during off-periods. If no such customer exists, the landfill could use its energy resources to

attract industry to locate near the landfill. The landfill should work with a local department of economic

development to develop a strategy for this option.

The economics of an electricity generation project depend largely on

external factors, i

ncluding the price at which the electricity can be sold,

available tax credits or other revenue streams such as renewable energy

certificates. If the purchasing utility pays only the avoided cost f

or the

electricity, an electricity ge

neration project may not be economically

feasible. Fortunately, electricity g

eneration projects are receiving more

favorable power purchase agreements (PPAs) because of growing

interest in renewable energy resources and an i

ncreasing number of

states with Renewable Portfolio Standards (RPS).

Th

e most common structure for an LFG electricity project is to sell the electricity to an investor-owned

utility, cooperative or municipal entity through a PPA. Typically, the electricity, including energy and

capacity, is sold at a fixed price with level of escalation, or at an indexed price based on an estimate of

short-run avoided cost, or a publicly available local market price mechanism. Negotiating an acceptable

interconnection agreement is important to a successful electric generation project. The interconnection

agreement can be a large cost variable and discussions should begin early in the project.

If an electric generation project is selected, the next step is to choose the type of power generation, which

depends on the amount of recoverable LFG, the expected quantity for at least 10 years and the gas quality.

If heat or steam and electric power are needed forms of energy, then a CHP project may be the

appropriate choice. Regardless of which generator type is used, the project will most likely need to be

sized smaller than the amount of available gas to ensure full-load operation of equipment. Therefore, the

project likely will have excess gas that will have to be flared. Table 3-10 summarizes the relationship

between technology options and the amount of LFG flow available for an LFG energy project.

Project Technology Options 3-16

Avoided costs are the

costs the utility avoids, or

saves, by not making the

equivalent amount of

electricity in one of its own

facilities, and would

include fuel costs and

some operating costs, but

not fixed costs.

LFG Energy Project Development Handbook

Table 3-10. Summary of LFG Flow Ranges for Technology Options

Technology

LFG Flow Range (at Approximately 50% Methane)

Electricity

Internal combustion engine

(800 kW to 3 MW per engine)

300 to 1,100 cfm; multiple engines can be combined for larger

projects

Gas turbine

(1 to 10 MW per gas turbine)

Exceeds minimum of 1,300 cfm; typically exceeds 2,100 cfm

Microturbine

(30 to 250 kW per microturbine)

20 to 200 cfm

Medium-Btu Direct-Use

Boiler, dryer and process heater

Utilizes all available recovered gas

Infrared heater

Small quantities of gas, as low as 10 cfm

Greenhouse Small quantities of gas

Artisan studio

Small quantities of gas

Leachate evaporation

1,000 cfm is necessary to treat 1 gallon of leachate per minute

Upgraded LFG

High-Btu/Pipeline-quality gas

400 cfm and up, based on currently operating projects

Alternative fuel (CNG or LNG)

Depends on project-specific conditions

cfm: cubic feet per minute CNG: compressed natural gas kW: kilowatt

LNG: liquefied natural gas MW: megawatt

State and local air quality regulations and limits also play a role in technology selection. Refer to local air

regulations for determining restrictions on technologies. For example, internal combustion engines may

not comply with nitrogen oxides emission requirements, and a gas turbine or microturbine may need to be

used. Stringent emission limits for various pollutants may require more extensive pretreatment of the LFG

or exhaust from gas turbines.

Regions of the country with more stringent air regulations offer opportunities for CNG or LNG

applications because use of these fuels in landfill vehicles or refuse collection and transfer fleets in place

of fossil fuels will lower emissions.

For more information about project economics and financing, see Chapter 4.

For more information about permitting requirements and relevant regulations, see Chapter 5.

Project Technology Options 3-

17